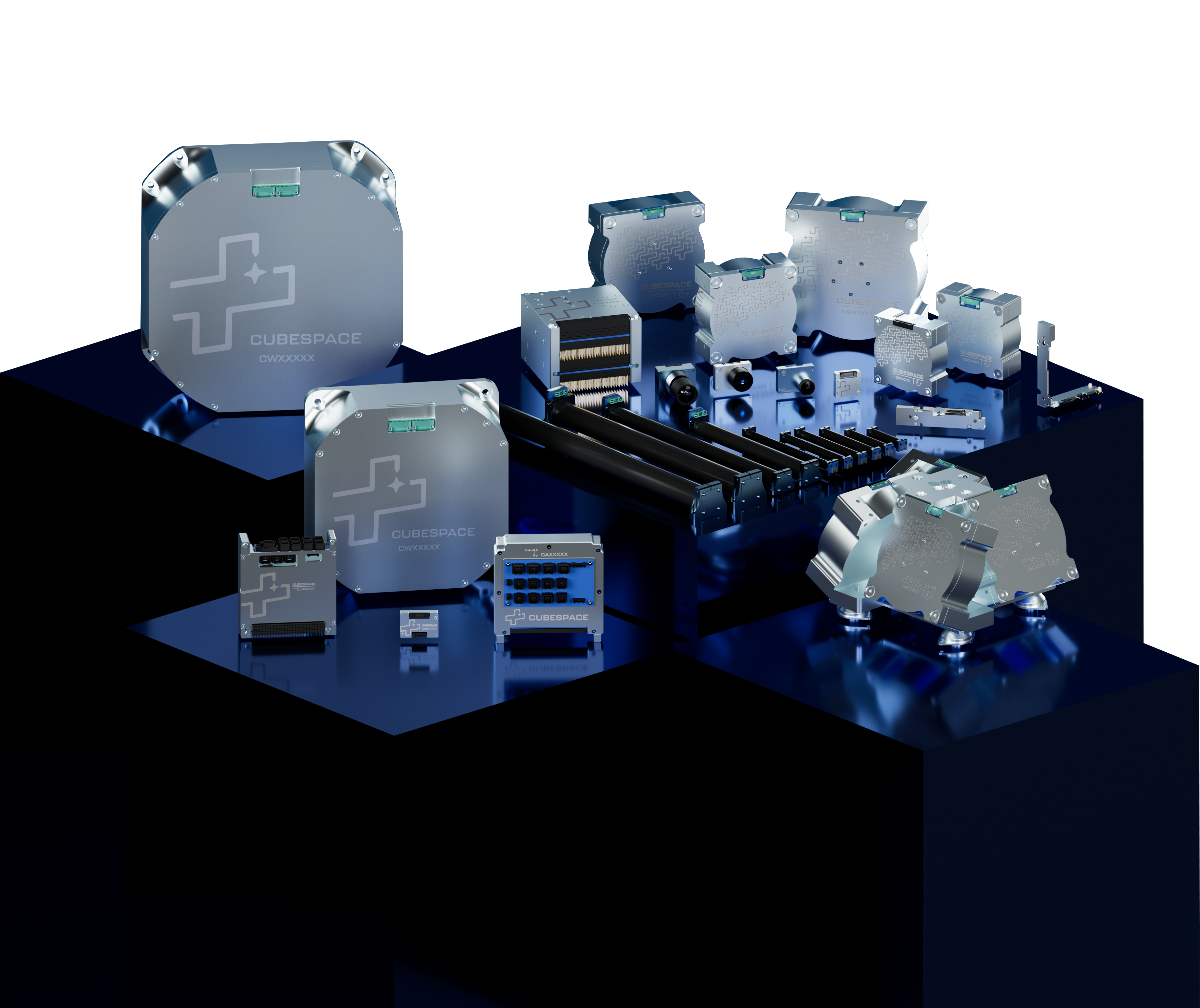

We are setting the global standard in control systems for satellites up to 1 ton and revolutionising how satellites are built. See how our innovative solutions can propel your mission to new heights.

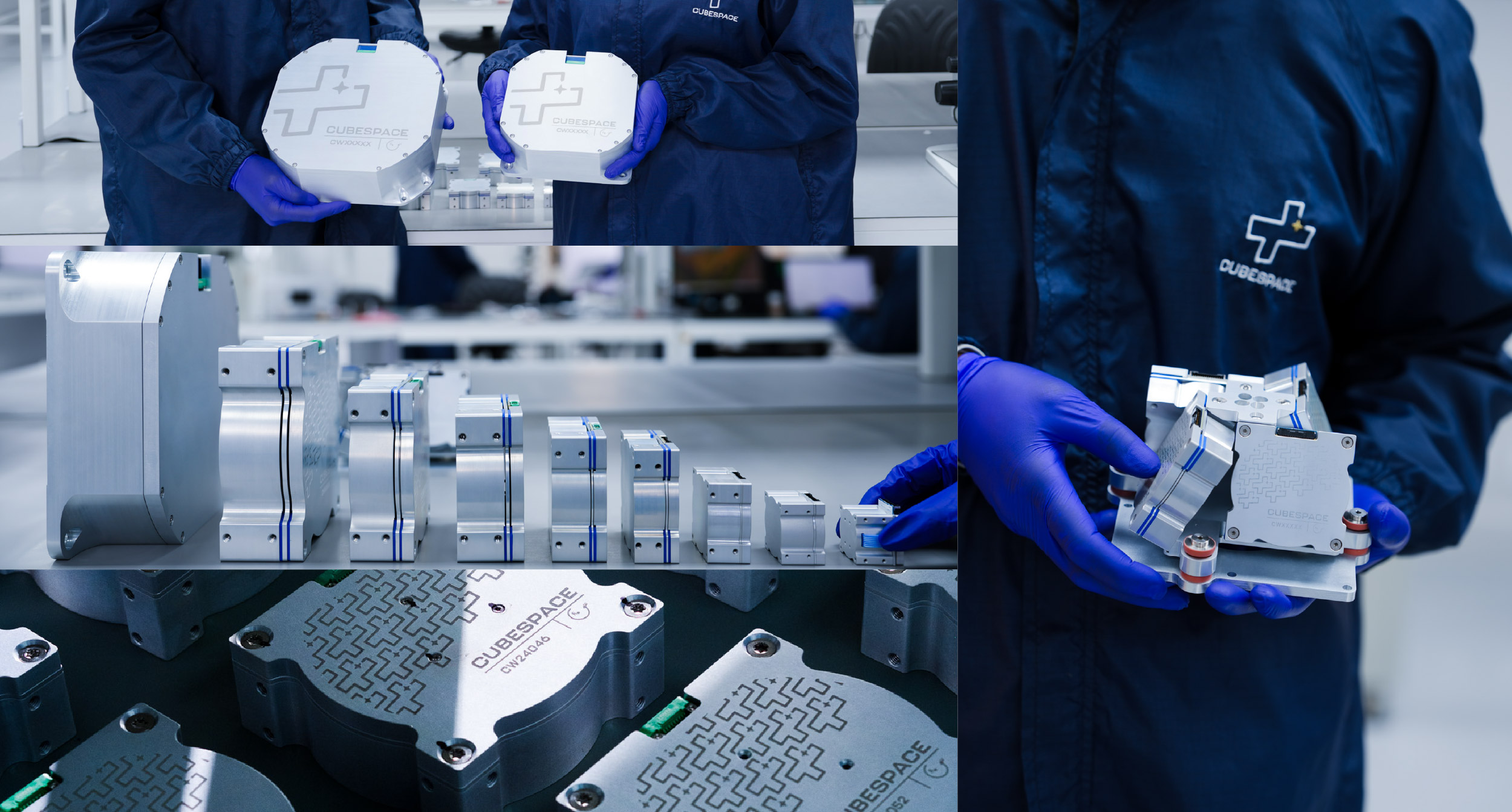

Our state-of-the-art 1,350m2 facility features an 80m2 ISO 7 certified cleanroom and 130m2 of specialized production space. This expansion has more than doubled our production capacity and allowed us to establish high-cadence production lines. Combined with advanced automation and our products being designed for manufacturability, we can now produce large volumes with unparalleled speed and efficiency.